EFFICIENCY OF JET AIR HAND DRYER

The hand dryers are built around vacuum motor technology. The power of compression of these motors allows, through a thin air outlet, to reach a high speed; the air then licks the surface of the skin and expels the water in the direction of flow. There are 3 types of architectures on this type of technology.

There are those who come directly from Asian countries, they have been around for many years. Their architecture makes it possible to place the hands vertically in a cavity between 2 blades of air. There are hand dryer construction simpler: the motor is placed over an air outlet nozzle. We just put our hands directly below. The air nozzles of this type of hand dryer can have many forms. Then there are the hand dryers where the user comes to put, at the height of the belly, hands in a ring. This ergonomics was initiated by JVD and is growing more and more. By rinsing the water with forced air, the projections fall in the flow direction. There is no evaporative drying system. For this type of hand dryer, there are 2 solutions: either the water is projected on the ground, or the water is collected in a tank. We must be aware that in the latter case, the solution involves regular maintenance to clear the reservation.

USAGE LEVEL

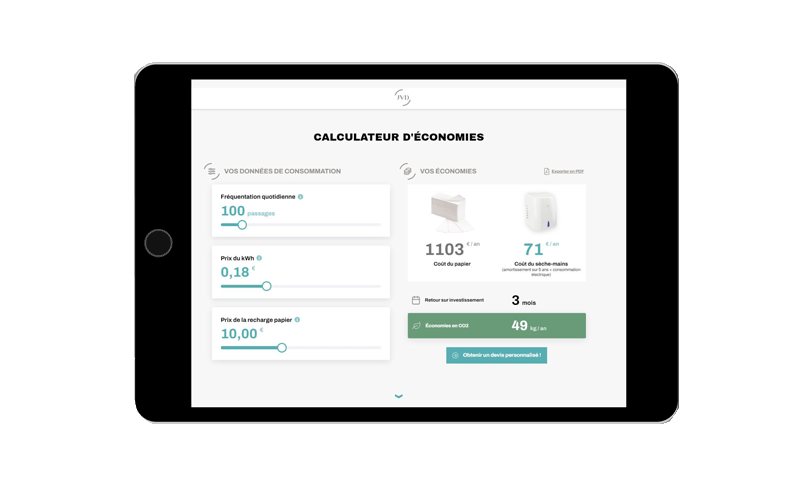

A hand dryer should provide a solution which is compatible with the level of usage of the washroom. For places with

little usage (< 50 visits daily), all three solutions are possible. For places with normal usage (50-250 visits daily), the cost of paper becomes prohibitive. For places with high usage (250-400 visits daily), jet air hand dryers are the only solution capable of guaranteeing cost control and a fast drying time. Lastly, for places with intensive usage (> 400 visits daily), the chosen hand dryer should have a brushless motor or an induction motor.